Embark on a journey through the world of installation estimates, exploring their significance across various industries. From unraveling the components to understanding estimation methods, this topic delves into the intricacies of creating accurate estimates.

As we delve deeper, we will uncover the challenges faced in estimating and strategies to enhance precision. Let’s unravel the mysteries behind installation estimates together.

Understanding Installation Estimates

An installation estimate refers to the process of predicting the cost, time, and resources required to complete a specific installation project. It plays a crucial role in various industries as it helps in budgeting, planning, and decision-making.

Importance of Installation Estimates

- Construction Industry: Installation estimates are essential in construction projects to determine the overall budget and timeline for completing a building.

- Home Renovation: Homeowners rely on installation estimates to understand the cost of remodeling projects such as kitchen renovations or bathroom upgrades.

- Technology Sector: Companies use installation estimates for setting up new IT systems, networks, or software applications.

Factors Influencing Installation Estimates

- Project Scope: The complexity and size of the installation project greatly impact the accuracy of the estimate.

- Materials and Labor Costs: Fluctuations in material prices and labor rates can affect the overall estimate.

- Experience and Expertise: The skill level of the installation team can influence the efficiency and accuracy of the estimate.

- Unforeseen Challenges: Unexpected issues or delays during the installation process can lead to variations in the estimate.

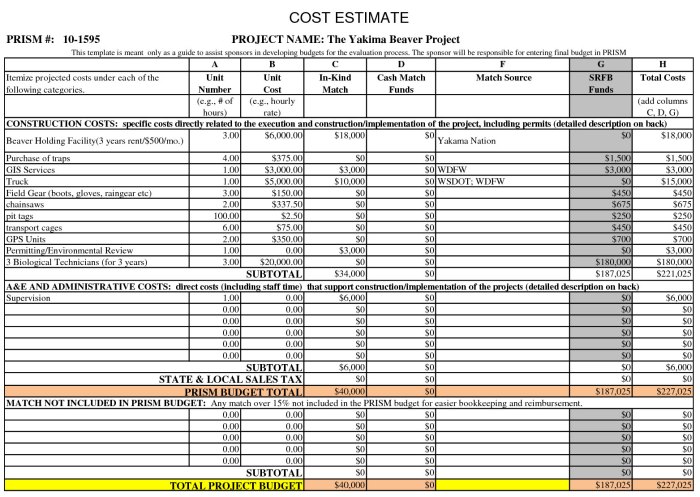

Components of an Installation Estimate

An installation estimate typically consists of various essential components that help in accurately determining the overall cost of a project. These components include material costs, labor costs, overhead costs, profit margins, and any additional expenses incurred during the installation process.

Material Costs vs. Labor Costs

Material costs refer to the expenses associated with the materials needed for the installation, such as equipment, tools, supplies, and any products required for the project. These costs can vary depending on the quality and quantity of materials used.On the other hand, labor costs pertain to the expenses related to the workforce involved in the installation process.

This includes wages, salaries, benefits, and any other compensation for the laborers performing the installation work. Labor costs are typically calculated based on the hours worked and the skill level required for the job.In an installation estimate, material costs are usually more straightforward to calculate as they involve tangible items with set prices.

In contrast, labor costs can be more variable and may require a detailed breakdown of the tasks to be performed and the time needed to complete them.

Tools and Software for Creating Installation Estimates

There are various tools and software available that can help in creating accurate installation estimates. Some commonly used tools include:

Estimating software

Specialized software programs designed for creating detailed estimates based on project requirements and specifications.

Spreadsheet programs

Utilizing programs like Microsoft Excel or Google Sheets to organize cost data, calculate totals, and create customizable templates for estimates.

Online calculators

Web-based calculators that can quickly estimate costs based on inputted data such as square footage, material prices, and labor rates.

Project management software

Platforms that integrate estimating tools with project management features to streamline the entire installation process from initial estimate to project completion.By utilizing these tools and software, contractors and project managers can efficiently generate accurate installation estimates that help in budgeting, planning, and executing projects effectively.

Estimation Methods

When it comes to calculating installation estimates, various methodologies are used to ensure accuracy and efficiency in cost projections. Let’s explore some common estimation methods, along with their advantages and disadvantages.

Unit Costing

Unit costing is a method where the total cost is estimated by multiplying the quantity of units required by the cost per unit. This method is straightforward and easy to understand, making it ideal for projects with clear and well-defined requirements.

- Advantages of Unit Costing:

- Simple and easy to calculate.

- Provides a detailed breakdown of costs.

- Disadvantages of Unit Costing:

- May not account for unique project requirements.

- Does not consider economies of scale.

Parametric Estimating

Parametric estimating involves using historical data and statistical modeling to calculate costs based on specific project parameters. This method is useful for projects with similarities to past projects where parameters can be easily quantified.

- Advantages of Parametric Estimating:

- Relies on data and statistical analysis for accuracy.

- Helps in quickly estimating costs for similar projects.

- Disadvantages of Parametric Estimating:

- Requires a significant amount of historical data for accuracy.

- May not be suitable for unique or complex projects.

Real-World Examples

In construction projects where the installation of standard components like doors and windows is involved, unit costing can be a suitable estimation method due to the repetitive nature of such tasks. On the other hand, for large infrastructure projects like bridges or highways where historical data is abundant, parametric estimating can be more appropriate for cost projections.

Challenges in Estimating

Creating installation estimates can be a complex task, often presenting various challenges that need to be addressed for accurate and precise calculations. Let’s explore some common challenges faced in estimating installation costs and strategies to overcome them.

Uncertainty in Project Scope

One of the key challenges in estimating installation costs is dealing with uncertainty in the project scope. Changes in project requirements or unforeseen complications can significantly impact the final cost. To overcome this challenge, it is essential to conduct a thorough initial assessment of the project scope and continuously communicate with stakeholders to address any changes promptly.

Inaccurate Data or Information

Another common challenge is working with inaccurate or incomplete data during the estimation process. This can lead to underestimating or overestimating costs, resulting in financial losses or missed opportunities. To improve accuracy, ensure that you gather relevant and up-to-date information, collaborate closely with suppliers and subcontractors, and utilize reliable estimating tools or software.

Market Fluctuations

Market fluctuations in material prices, labor costs, or regulatory requirements can pose a significant challenge when estimating installation costs. To mitigate the impact of market fluctuations, stay informed about industry trends, build relationships with suppliers to secure competitive pricing, and regularly update your cost database to reflect current market conditions.

Overlooking Hidden Costs

Estimators may often overlook hidden costs such as permits, inspections, or site preparation, leading to inaccurate estimates. To address this challenge, create a comprehensive checklist of all potential costs associated with the installation project, including indirect expenses, to ensure a more realistic estimate.

Lack of Experience or Expertise

Estimating installation costs requires a certain level of expertise and experience in the field. Lack of experience can result in inaccurate estimations and potential project delays or budget overruns. To improve precision, consider partnering with experienced estimators, investing in training programs for your team, and seeking mentorship from seasoned professionals in the industry.

End of Discussion

In conclusion, installation estimates play a crucial role in project planning and budgeting. By mastering the art of estimation methods and overcoming challenges, businesses can ensure the success of their projects. Dive into the world of installation estimates and elevate your project planning game today.

Question Bank

What factors influence the accuracy of installation estimates?

Factors like material costs, labor costs, project scope, and unexpected variables can impact the accuracy of installation estimates.

What are some common challenges faced when creating installation estimates?

Common challenges include inaccurate data, changing project requirements, and unforeseen complications during installation.

How can one improve the precision of installation estimates?

Improving data accuracy, staying updated on industry trends, and leveraging advanced estimation tools can enhance the precision of installation estimates.